Analisis dan Desain Klasifikasi Produk sebagai Dampak Covid 19 pada Industri Furnitur

DOI:

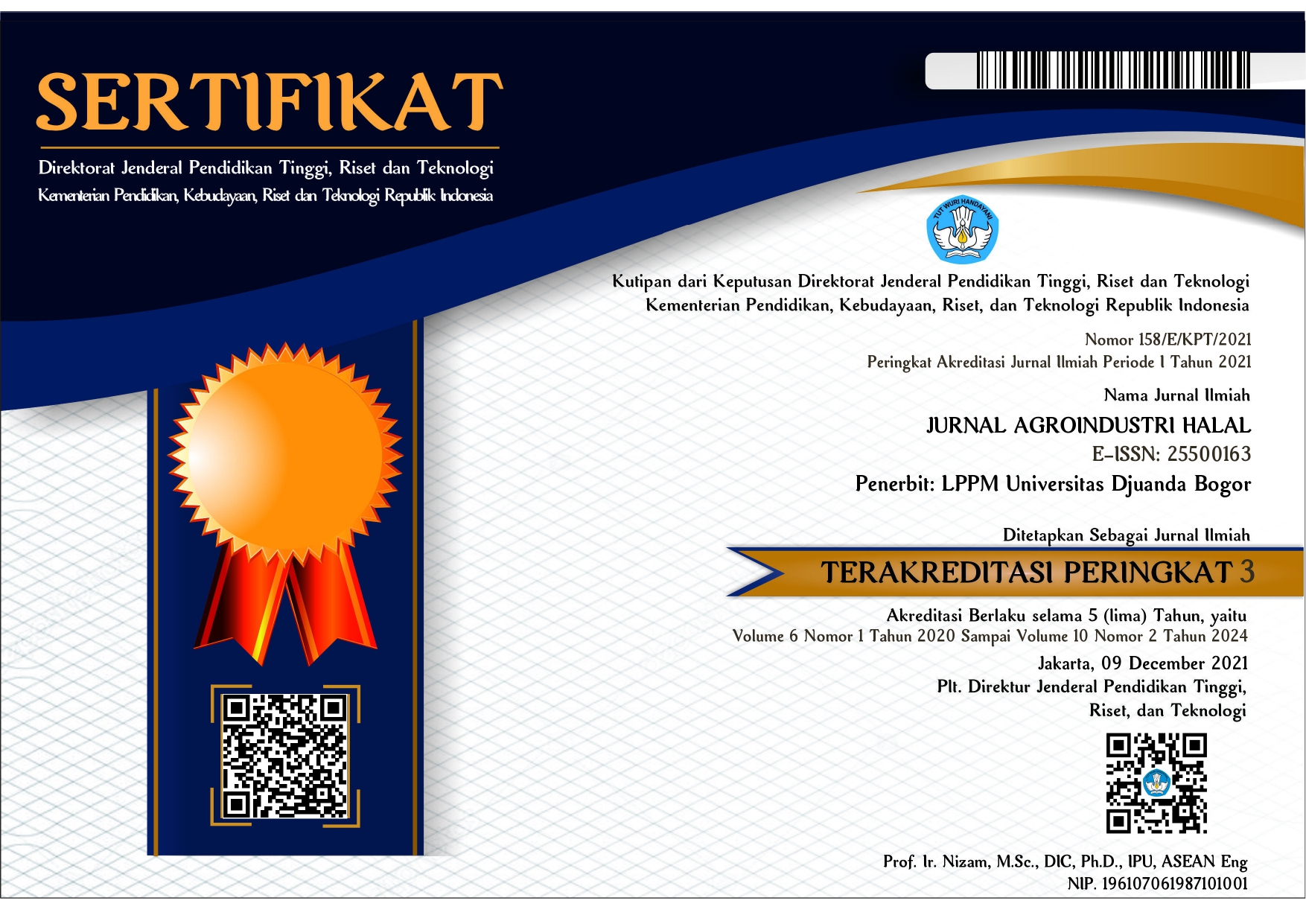

https://doi.org/10.30997/jah.v9i1.8319Keywords:

ABC-XYZ, Covid-19, Furniture, classification, inventory managementAbstract

The furniture industry is one of the industries affected by Covid-19 which has caused a change in inventory management. The purpose of this study is to analyze changes in product classification based on the ABC-XYZ analysis for 2019-2022. The results of the study show that there has been a change in product classification from 2019-2022. The Covid-19 pandemic has resulted in a decrease in demand for wardrobe products at PT XYZ. A CV value above 30% indicates that the product demand is very difficult to predict, especially during the Covid-19 pandemic. Demand for 2022 has improved compared to the previous two years. The results of the ABC-XYZ classification show that companies need to exercise good control over demand for class AZ even though they still have a large CV value. A CV value that is too large can be caused by the data forming seasonal data, even though the furniture product is not a seasonal product. This happened because there were sales that fell and had an impact on the company's operations, especially product inventory. There are seven products that are in class AZ and are priority products that need inventory control compared to other classes.

References

Brata K P. Sari S. (2020). Analisis kelasifikasi ABCXYZ dan perbandingan metode EOQ, POQ, serta Min-Max untuk pengendalian persediaan komponen Auto Purchase pada Kind 19 Transmission. Seminar Nasional Teknik Industri Universitas Gadjah Mada.

Dataindonesia.id. (2022, 27 Maret). Industri Lemari Tumbuh 8.16% pada tahun 2021. Diakses pada 21 Desember 2022, dari https://dataindonesia.id/sektor-riil/detail/industri-furnitur-tumbuh-816-pada-2021

Evdokimova, S. A. (2021, October). Segmentation of store customers to increase sales using ABC-XYZ-analysis and clustering methods. Journal of Physics: Conference Series, 2032, 1, 012117.

Herlambang, C. A., & Parung, J. (2021). Information System Design and Inventory Management On Pharmacy Business Within ABC-XYZ Analysis Method. Airlangga Journal of Innovation Management, 2(2), 194-205.

Muller, M. (2011). Essential of Inventory Management Second Edition. Amacom.

Muslim, A. C. (2020). Perancangan Strategi Total Productive Maintenance. JITMI (Jurnal Ilmiah Teknik Dan Manajemen Industri), 3(2), 83-90.

Ratnasingam, J., Khoo, A., Jegathesan, N., Wei, L. C., Abd Latib, H., Thanasegaran, G., ... & Amir, M. A. (2020). How are small and medium enterprises in Malaysia’s furniture industry coping with COVID-19 pandemic? Early evidences from a survey and recommendations for policymakers. BioResources, 15(3), 5951-5964.

Silver, E A., Pyke, D. F., & Thomas, D. J. (2017). Invnetory and Production Management in Supply Chain Fourth Edition. New York (USA): CRC Press.

Stevic, Z., & Merima, B. (2021). ABC/XYZ Inventory Management Model in a Construction Material Warehouse. Alphanumeric Journal, 9(2), 325-334

Stojanović, M., & Regodić, D. (2017). The significance of the integrated multicriteria ABC-XYZ method for the inventory management process. Acta Polytechnica Hungarica, 14(5), 29-48.

Swastomo, G. I., Ridwan, A. Y., & Santosa, B. (2020). Inventory Policy For After Sales Spare Parts To Minimize Overstock Using Periodic Review And Abc-xyz Classification In PT PQR. eProceedings of Engineering, 7(2).

Zenkova, Z., Musoni, W., & Tarima, S. (2020, October). Accounting for deficit in ABC-XYZ analysis. In 2020 5th International Conference on Logistics Operations Management (GOL), 1-6

Downloads

Published

How to Cite

Issue

Section

License

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

Authors who publish with Jurnal Agroindustri Halal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution 4.0 International License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in Jurnal Agroindustri Halal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgement of its initial publication in Jurnal Agroindustri Halal.

- Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work